Hitachi Rail has commercialised a cutting-edge technology for real-time infrastructure monitoring and predictive maintenance, following extensive UK-led research and development. This milestone, achieved in collaboration with Connected Places Catapult, introduces a new rail maintenance solution that promises to enhance punctuality and safety.

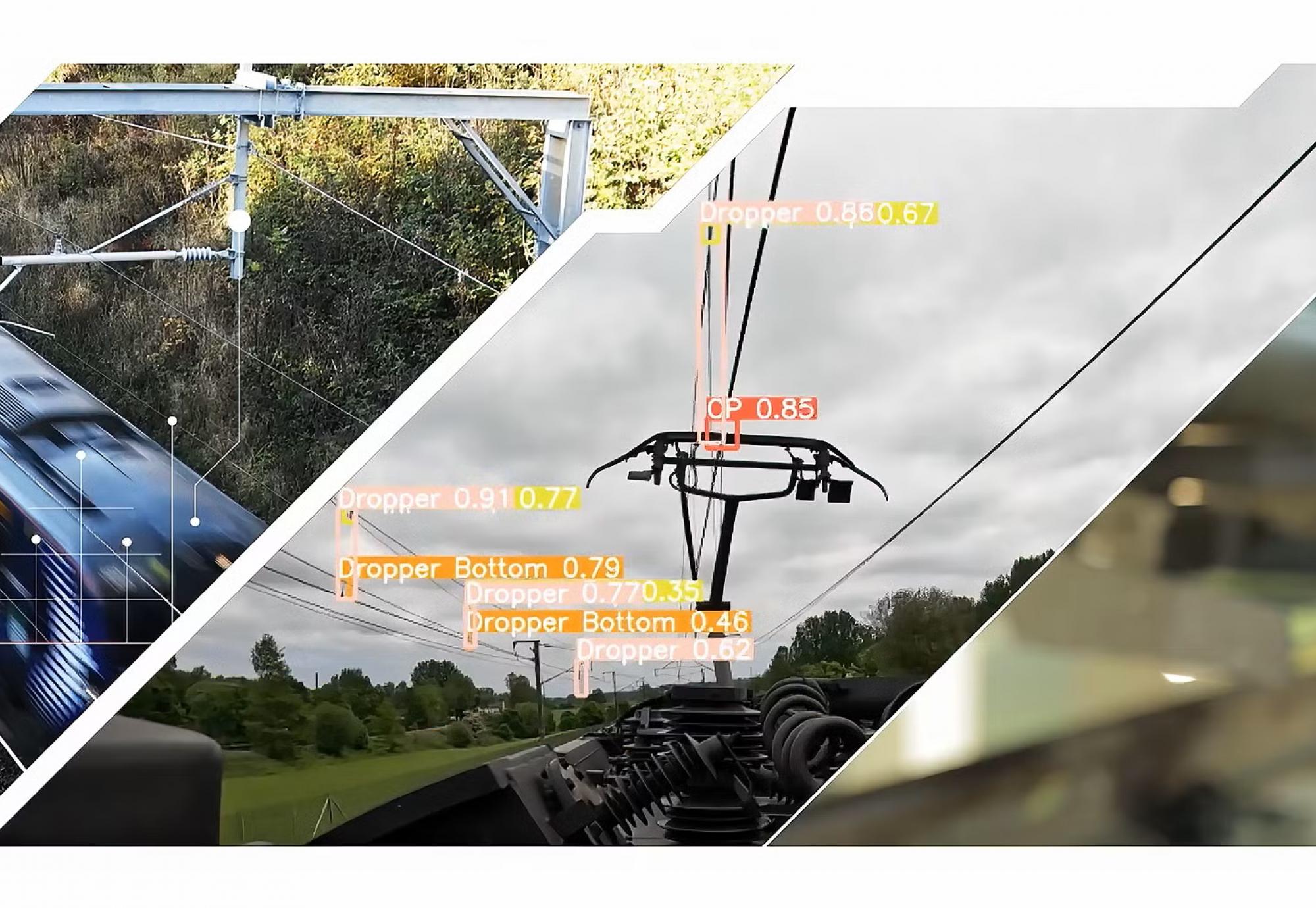

Hitachi's digital overhead line monitoring technology is part of their global digital asset monitoring platform, HMAX. This innovative solution uses cameras mounted on trains to monitor overhead lines in real-time, with machine learning algorithms automatically identifying potential faults and pinpointing maintenance needs.

The journey began in 2021 when Connected Places Catapult facilitated a technical collaboration between Hitachi Rail, LNER, and Network Rail. This partnership led to a successful six-month trial on the East Coast Main Line, where the technology proved its effectiveness. The Catapult's support was crucial in understanding end-user requirements and developing new collaborative working models, ultimately bridging the 'valley of death' in tech innovation.

Building on the trial's success, Hitachi further refined the technology, integrating it into their HMAX platform. HMAX enhances railway management by consolidating operational data from various assets and infrastructure into a single platform, optimizing resource utilization. Besides real-time monitoring, HMAX enables virtual simulations of the physical environment, accelerating the evolution of railway systems.

Ben Earle, IM and Digital Services Manager at Hitachi Rail, said:

“The UK’s railway ecosystem had an important part to play in the development of this technology, which is now available to infrastructure operators worldwide.”

By working with Connected Places Catapult, we were able to collaborate with industry and successfully test this product in a real-world environment.”

Image credit: Hitachi